I recently had a chance to visit Taylor’s Bell Foundry in Loughborough. Although I have lived in Loughborough for nearly 30 years this was only my 2nd visit. It was fantastic to see our Victorian industrial heritage in action as a working factory as it has done since 1859. This is unique because it’s not a working museum. The site has continuously produced bells since 1859 as a successful business. So far Taylor’s have cast over 25,000 bells that are hung in over 100 counties.

Before entering the factory, a walk around the outside of the buildings showed they were in good condition. This is because the whole site is being refurbished for a relaunch in the autumn of 2024.

The edifices showcase numerous imposing structures, there were the expected chimneys designed for the dispersion of smoke from the furnaces. Additionally, a prominent bell tower graces the locale, producing resonant bell chimes that have the potential to entice potential customers.

The sizes of the doors are quite remarkable. They are needed so that the largest of the bells can be extracted. The largest bell in St. Paul’s Cathedral is Great Paul. It was manufactured at Taylor’s, and it weighs in at 16 tons.

Moving inside the works there is quite a collection of heavy machinery to produce the moulds for the casting processes.

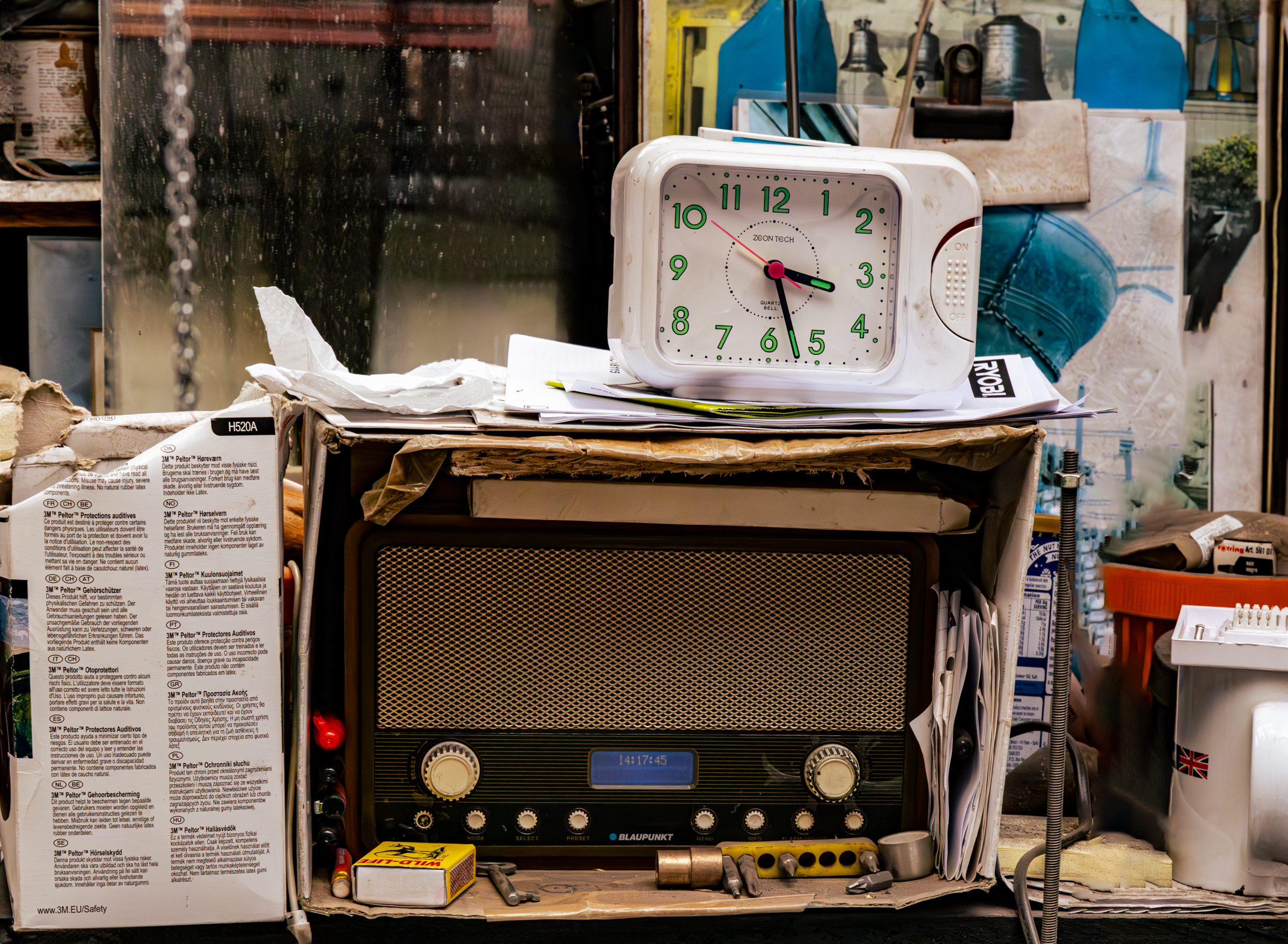

Some of the workbenches included years of personal mementoes from the workers.

When the moulds are complete they are ready for the casting process. I was lucky enough to be there on a day when the casting was happening. The initial stages are to get the molten metal to temperature and remove any slag.

When the metal is up to temperature it is transferred to a vat ready for pouring.

The final step is pouring the molten metal into the moulds.

Once the cast bells have been removed, work must be done. The bells have to be tuned and fixtures and fittings added.

I will return in the autumn of 2024 to look around the new visitor centre.

For more information visit https://belltrust.co.uk/